The Ultimate Guide: Getting to Know Paper Cups

Ganyuan

2024 年 11 月 29 日

Disposable paper cups are made from raw paper that goes through some processing, they’re shaped by machines and then glued together to create a sturdy container. These cups are perfect for holding cold drinks or hot beverages like juice and coffee, making them super convenient for our everyday needs. This article talks about how paper cups came to be and how they’ve evolved over time, plus the different types out there so you can get a quick grasp on what they’re all about.

Why are paper cups chosen by consumers?

Updating of production technology

The paper cup arose in the 20th century as a result of a health crisis, when the use of reusable cups led to the spread of infectious diseases such as tuberculosis, and a lawyer and his business partner invented the first paper cup, the “Health Kup”.

Thanks to the continuous progress of production technology, the waterproof coating inside the paper cups from wax coating to PE coating, to biodegradable coatings, and the development of machinery has allowed for the continuous improvement of production efficiency, from the initial low-speed machines to the current high-speed machines, to meet the needs of a large number of consumer groups.

Rapid development of the consumer goods industry

The rapid development of the consumer goods industry has promoted the prosperity of the paper cup market to a certain extent. With the improvement of residents’ income level and the change of consumption concepts, more and more consumers are dining out or buying takeout, which has driven the growth of demand for disposable tableware such as paper cups.

In addition, consumers are more pursuing consumption experience and have put forward higher requirements for the packaging and quality of beverages. As the most important packaging material, the market demand for paper cups continues to increase.

Changes in environmental protection concepts

As disposable tableware, paper cups are hygienic, environmentally friendly, inexpensive, and can effectively block the spread of diseases, and are popular among consumers.

Sustainable development has become a global consensus, and many countries have adopted a “plastic ban” policy, which has also promoted the global trend of paper cups replacing plastic cups. The paper cup industry will pay more attention to sustainable development and green production, and reduce the impact on the environment by adopting environmentally friendly materials and improving resource utilization.

How to distinguish different paper cups?

Materials

Raw paper: the source material are wood pulp fibers, but according to different grammage and different processing methods made of paper will be used in different areas of the scene.

Kraft paper: The kraft paper used to make paper cups is usually unbleached, ranging in color from light brown to brown, and is about 300 GSM, which is thicker and can withstand higher temperatures and pressure.

White cardboard: White cardboard is usually used for the outer layer of double-layer paper cups and cannot be used for the inner layer in direct contact with food. Due to its smooth and beautiful surface, it is suitable for printing various LOGOs for brand promotion.

Food-grade base paper: Bleached food-grade paper, ranging from 160-300GSM, meets food safety standards and ensures that no harmful substances are released when in contact with food or beverages. It is the most commonly used material for paper cups.

Corrugated paper: mainly used to insulate heat, increase strength, and also for beautiful shape. Commonly used corrugated paper cups are used for the outer layer, and the pattern can be designed. Common ones include twill corrugated and S-shaped corrugated.

Waterproof layer: The main function is to prevent liquid leakage and keep it safe for use

Wax coating: This is a coating material that was used more frequently in the early days, but it has now been abandoned. Although it can prevent leakage, it is only suitable for beverages with lower temperatures and is not environmentally friendly.

PE: The most popular choice on the market. PE (Polyethylene) is a thermoplastic that is non-toxic, low-temperature resistant, and chemically stable. It is usually used in the inner and outer layers of paper cups and is waterproof and oil-proof. Some consumers worry that this plastic will melt at high temperatures and enter the human body, causing danger. To be honest, this worry is unnecessary because PE plastic particles are generally coated on paper at a high temperature of 300 degrees Celsius, but the beverages we usually drink do not reach this temperature and are safe.

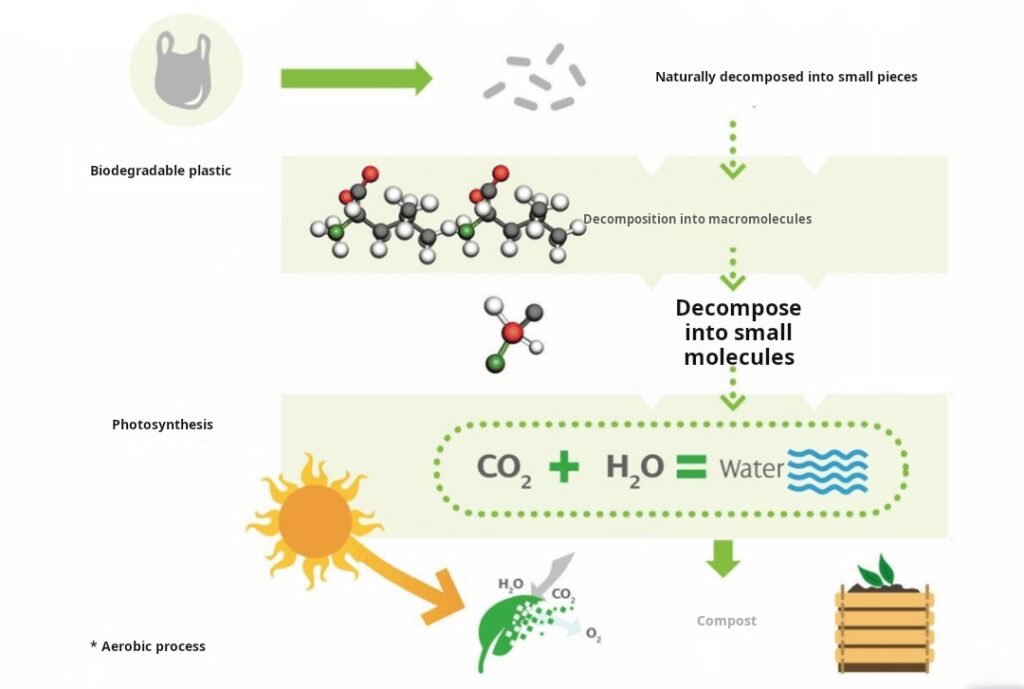

PLA: Many consumers mistakenly believe that PLA paper cups are made of PLA. In fact, this is not true. PLA paper cups only have a waterproof layer made from various plant fibers, the so-called PLA, not the paper cups themselves. Of course, compared with PE coating, its biodegradable advantage is obvious.

Water-based coating: Organic degradable molecular materials are covered on the paper through a composite machine to make the surface of the paper smooth and flat. The paper and the coating are tightly bonded to achieve a waterproof and oil-proof effect.

size

We can see paper cups of various sizes on the market, which are designed to hold different liquids for different consumers in different usage scenarios.

4oz: Mostly mini tasting paper cups used in supermarkets

8oz: Usually suitable for children, ideal for family gatherings, coffee chains, etc.

12oz: Generally, coffee shops and chain stores will choose this size, which is convenient to carry without excessive quantity, and meets daily needs. Whether it is on the way to work or in the afternoon, it can provide enough capacity and high cost performance

16oz: The capacity is increased based on 12oz to meet the needs of people who want a larger capacity

For more sizes, you can refer to the paper cups produced by Ganyuan, which have good quality, provide customized services, and tailor-made procurement plans for customers.

Appearance

Single-layer cup: A single-layer cup is a paper cup made of only one layer of food-grade paper. This paper cup is suitable for cold drinks or drinks with low temperatures.

Double-layer cup: A common choice for drinking coffee. Compared with single-layer paper cups, double-layer paper cups have an additional external patch, which can not only print various patterns and LOGOs for brand promotion, but more importantly, it can isolate the heat of the internal liquid to prevent burns.

Corrugated cup: Similar to the insulation principle of double-layer paper cups, it is more creative and aesthetic in appearance, which increases the fun of paper cups.

Handle cup: This red paper cup is more used in the Middle East and the Gulf region, and is relatively rare in Europe and the United States. It is to add a handle to the single-layer cup. To be honest, the handle cup is to prevent burns and is safer. From a more practical point of view, the double-layer cup is more practical than the handle cup, and the cost is better controlled.

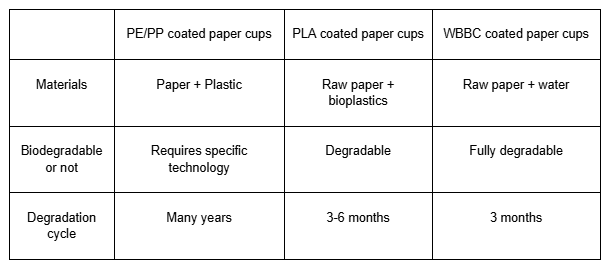

Comparison of the environmental performance of paper cups

As countries around the world are banning plastic, more and more consumers are paying attention to the environmental friendliness of products. The following table will intuitively show the environmental performance of various paper cups.

Paper cup preferences in different markets?

North American:

Pursuing product appearance and quality, high customization requirements, medium to high requirements for product weight, usually 210-320GSM, and degradable materials have gradually become popular in recent years.

European:

There are strict regulations, pursuit of environmental protection, and the highest quality requirements. The paper used is usually above 230GSM, and the highest requirements for the degradability of the material. The relevant certification is the most stringent.

Asian:

The Asian market has from low-end to high-end, covering the widest range. Paper requirements cover all from low to high. Compared with other countries, Japan in Asia has the strongest environmental awareness and is the most stringent on paper cup materials.

Other markets

The rise of emerging markets is a major trend, and it is bound to go through a process from price sensitivity to the pursuit of quality and environmental protection.

How to choose the right paper cup?

Step 1: Type of cup

Clarify the usage scenario. What do you use your paper cups for? Hot drinks or cold drinks? Single-layer cups are suitable for cold drinks and are cheaper. Double-layer cups and corrugated cups are suitable for hot drinks and are safer to use.

Step 2: Cup Size

If it is a common takeaway store or juice shop, the size of 12-16oz is suitable for adults. Of course, smaller sizes such as 8oz can be provided for children. If it is a tasting cup in a supermarket, 4oz is generally the most suitable and will not be wasted. Larger sizes are set for some special groups.

Please note: It is best to use the common size in the market, so that it is convenient to compare the prices of different suppliers, when you change the supplier, so that a new matching supplier can be found quickly.

Step 3: Customize LOGO

Most paper cups need to be printed with their company’s LOGO when they are used, which is convenient for brand promotion and more beautiful. However, when designing the LOGO, you should pay attention to the setting of the printing area and the selection of printing colors. Small printing areas and fewer colors are not only environmentally friendly, but also cheaper.

Conclusion

From this article, you will learn about the market development of paper cups, and also have a better understanding of the materials, sizes, and types of paper cups. The research and development of environmentally friendly materials is the future trend of paper cups, and you should closely integrate your products with future trends.

price?