European supermarket plastic ban and solutions in 2025 (13)

Ganyuan

2025 年 6 月 6 日

When a customer spills hot coffee because the cup is too hot to hold, you lose not only a drink —— but also your brand reputation and repeat customers.

The truth: When the San Francisco cafe Brew & View switched to corrugated paper cups, the rate of bad reviews dropped by 68%, and the percentage of customers who took the initiative to post about the cups increased by 240%.

Why are global brands switching to corrugated paper cups?

Pain point terminator: Hot hand? Leakage? Soft collapse?

-Physical level insulation: the corrugated air layer makes the wall temperature of the 90℃ hot drink cup only **43℃** (actual measurement data)

-Pressure resistance and deformation prevention: 340g thick cardboard can carry **5kg** (compared with ordinary cup 1.2kg)

-100℃ non-leakage: food grade PE coating + laser sealing process

Hidden profit growth points

(Source: 2024 Global Food and Beverage Packaging Trends Report)

真实案例:

韩国连锁奶茶品牌“八公茶”使用定制瓦楞杯后 ——

✓ 外卖平台好评率提升41%

✓ 品牌话题TikTok观看次数突破1.2亿

The global pass code for corrugated paper cups

Environmental competitiveness

-Dual environmental certification: FSC forest certified paper + recyclable PE coating

-EU access key: Pass EN13432 compostable test (2025 plastic tax exemption)

Visual economy dividend

-Wave 3D texture: shelf recognition increased by **300%** (consumer eye movement experiment)

-Ins wind color series: Morandi gray/olive green/ oat white has become an international hit

-Customized gold area: the middle part of the cup body is left blank, with the highest rate of scanning code

Avoid the procurement trap: 4 truths about corrugated paper cups

1. Thicker = heavier

✅ Check the bottom weight mark (high quality corrugated cup> 300g)

❌ Low price trap: more than 30% of recycled paper will reduce thermal insulation

2. The core of leak prevention is process

-The liner must cover the lower edge of the cup rim by 1cm (to prevent condensation water penetration)

-Cup cover slot shall be tested by three presses

3. Controllable environmental costs

Cost breakthrough in 2024:

+ The gap between corrugated cup batch price and ordinary anti-scald cup is reduced to +8%

-China’s new base in Guangxi reduces international logistics costs by 35%

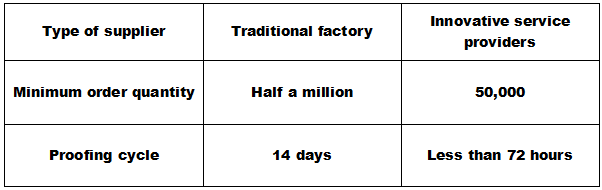

4. Custom order myth

Summary: Action list: 4 questions to ask when purchasing corrugated cups

1. “Can you provide the EU EN13432/FDA 21 CFR certification documents?”

2. “Does the glue used in the corrugated layer of the cup body meet FDA food contact standards?”

3. “Do you support logo color printing with a minimum order of 30,000?”

4. “Where can I see the extreme temperature (-5℃~100℃) test report?”

Recent News